Seico, your project partner from A to Z for trenchless rehabilitation of gravity-and pressure pipes.

Seico, your project partner from A to Z for trenchless rehabilitation of gravity-and pressure pipes.

Seico in your contractor for trenchless rehabilitation of gravity-and pressure pipes.

We are specialized in providing tailor made solutions, your project partner from A to Z.

Today a majority of cities are facing significant challenges in pipe infrastructure asset management.

A large part of the current infrastructure was built by previous generations and is at or nearing its end of life.

In the mean time the society has evolved in such a way that the socio-economic impact of public works in densely populated area’s is not longer tolerated and any hindrance must be strictly limited.

Breaking up a road in the city centre to replace a pipe is only considered as a last resort.

In the last few decades the industry has strongly invested in the development trenchless rehabilitation techniques (pipe bursting, U-liners, GVK panels, CIPP liners, SIPP lining, etc...) which have been adopted by city authorities and private companies to increase the life expectancy of their pipe infrastructure with the following benefits compared to cut and cover techniques:

|

Environment: every meter excavation avoided has a tremendous positive impact on the environment |

|

Overall cost: significantly lower for trenchless rehabilitation |

|

Surface footprint: very limited which is mandatory for cities |

|

Project duration: much shorter, meaning the necessary downtime of the pipe is limited |

Proud partner of IBB16® technology

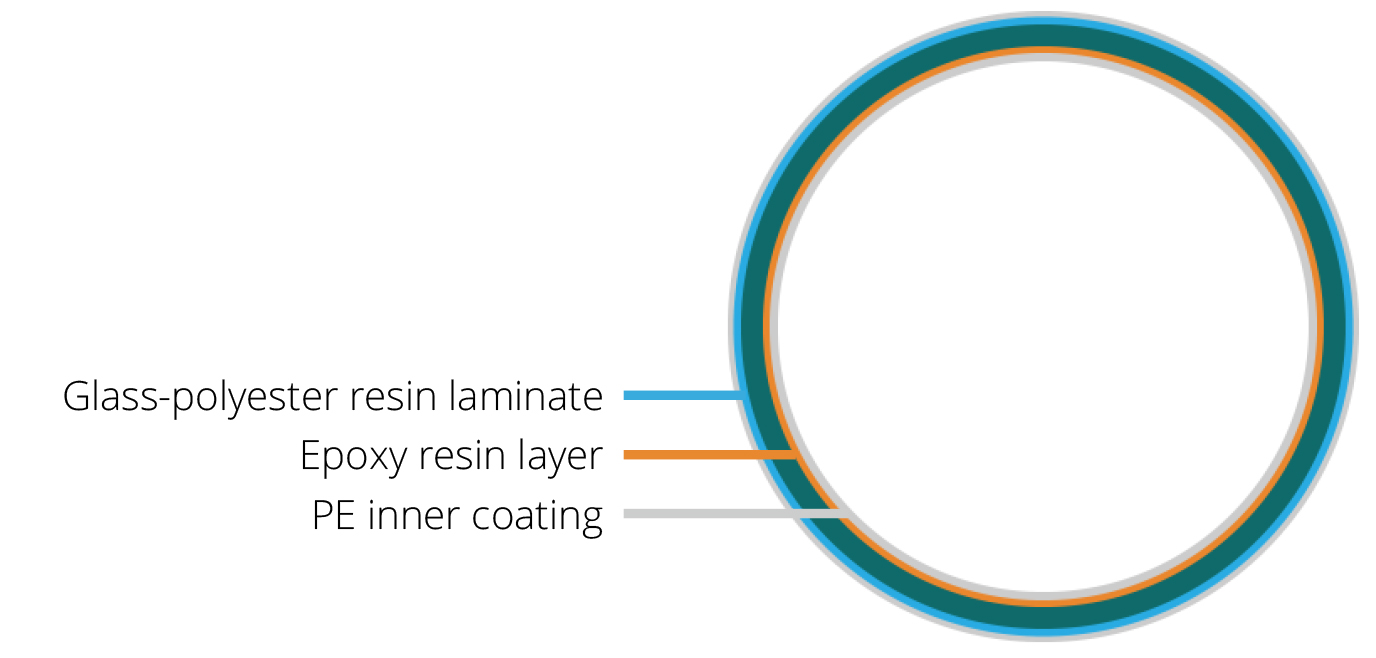

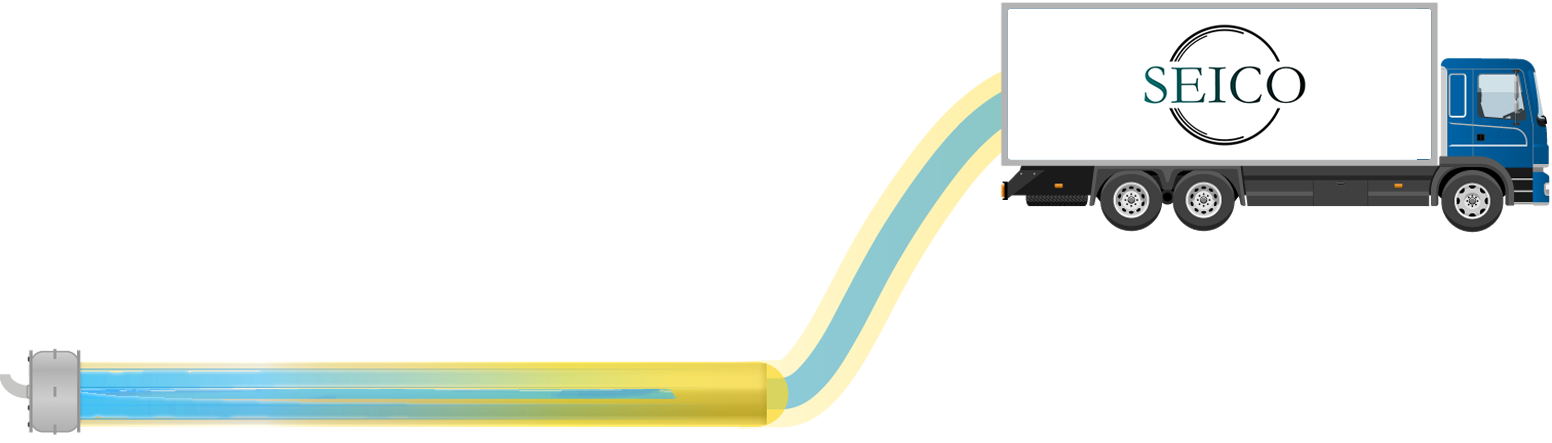

IBB16® is a hybrid hose pipe relining (without bonding to the old pipe – class A as per ISO 11295) applicable for the rehabilitation of pressure pipes.

The system combines two pipe liners with different properties to achieve the required criteria for the rehabilitation of pressurized pipes.

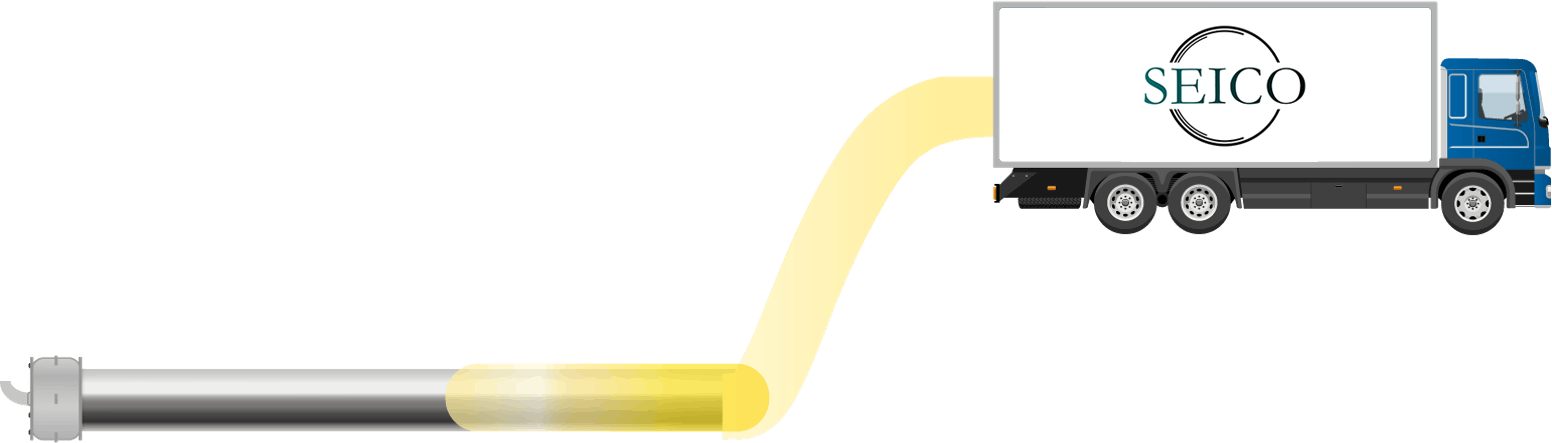

UV-method: the first layer is a rigid laminate of fiberglass and polyester resin and provides the structural strength of the system. The lining is prefabricated, drawn into the pipe, inflated and cured by UV light.

Inversion method: the second layer is a thin and flexible felt lining with a solid PE inner coating. The felt liner is impregnated with epoxy resin and installed via the inversion method, cured with steam. This layer gives a smooth and very high-quality finish.

High-pressure cleaning of the pipe to be rehabilitated

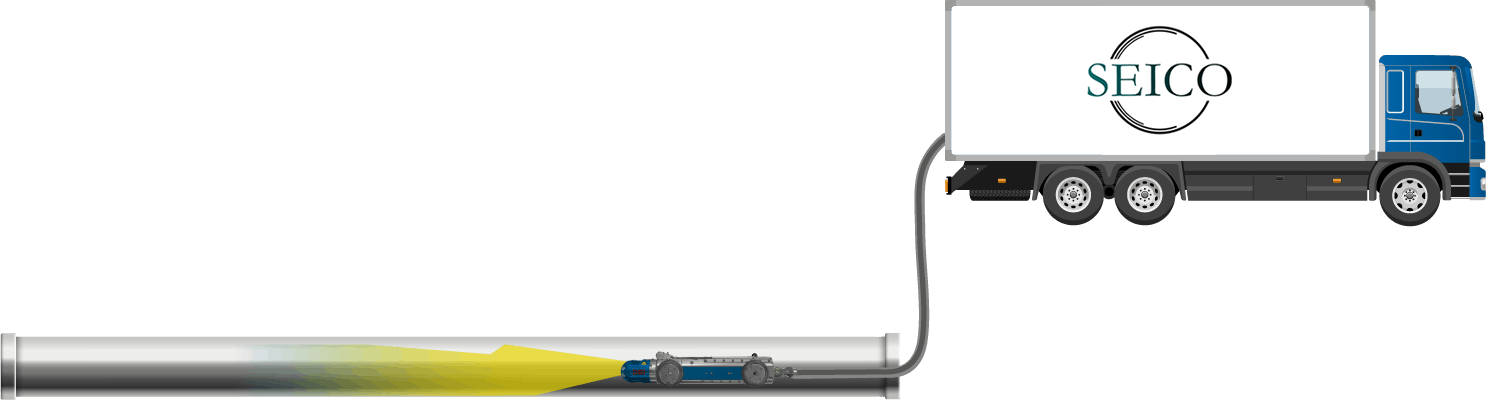

Pipe inspection by robot inspection - Search for root ingrowths or similar

Milling work to free the pipe from protruding hindrances

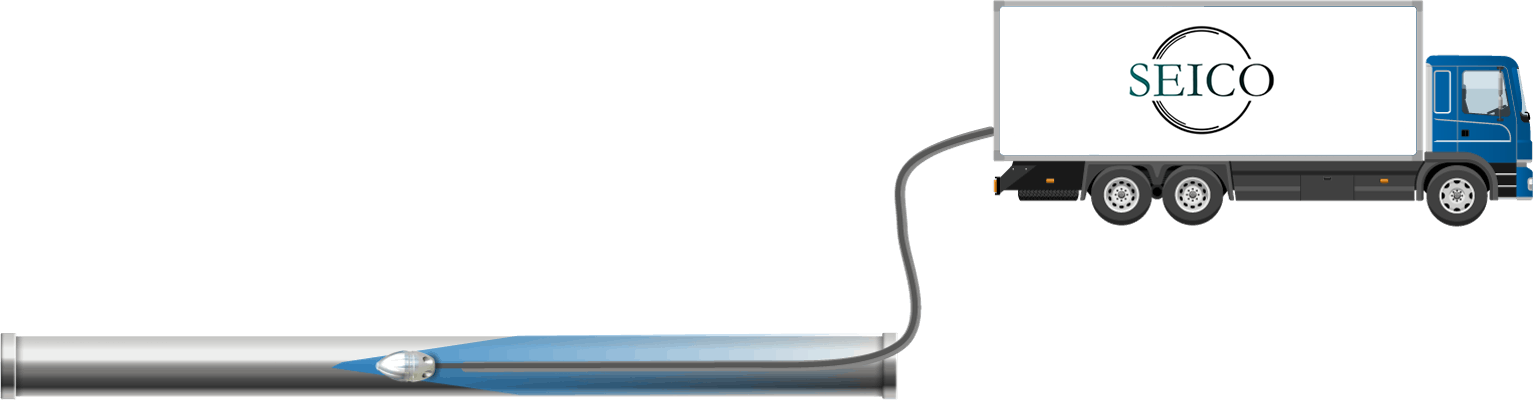

Second high-pressure cleaning of the pipe to be rehabilitated

Installation of the UV liner including curing

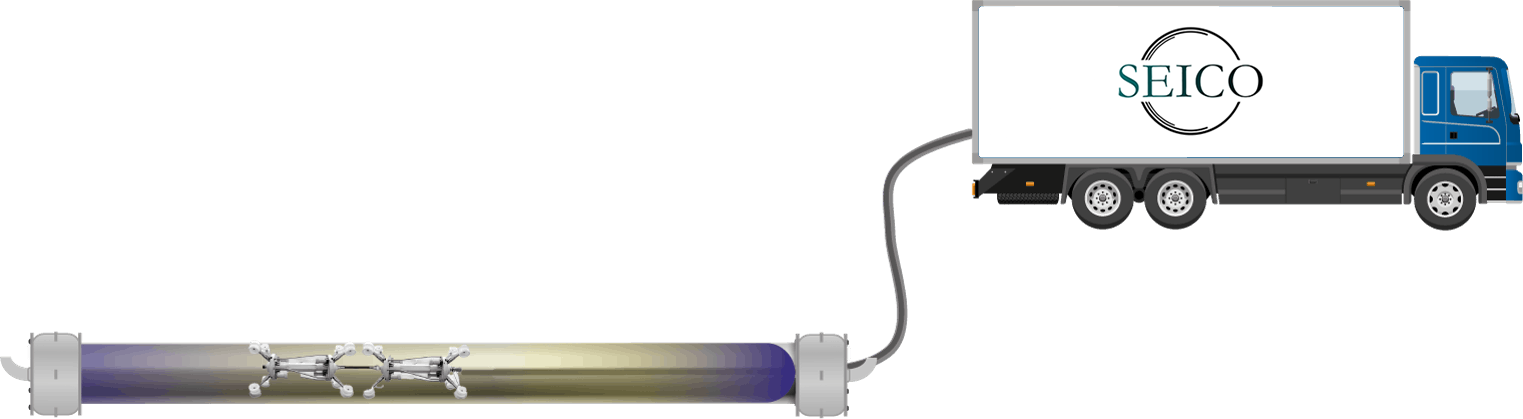

Installation of the 2nd layer INVERSION - Steam curing Epoxy + PE coating

Final inspection and pressure test

Shanghai, China | Moscow, Russia | Kiev, Ukraine | Lodz, Poland | Lviv, Ukraine | Florence, Italy | Shengdou, China | Oslo, Norway | Calabria, Italy | Prague, Czech Republic ...

IBB16 CIPP system tested for seismic conditions as per recognized standard

“Teicordia GR-63-CORE Zone 1, 2, 3 & 4“.

Safety factor achieved 16.2 times of the required loading –

Testing done by accredited SGS laboratory in South Korea.